Search

Inventory management is one of the biggest challenges facing last mile distributors (LMDs) operating in emerging markets.

“Across the board LMDs struggle with getting reliable information on products and suppliers, negotiating prices and payment terms, and with maintaining efficient stock levels whilst importing in small quantities,” according to a 2019 report from the Global Distributors Collective on the state of last mile distribution. (Download Report)

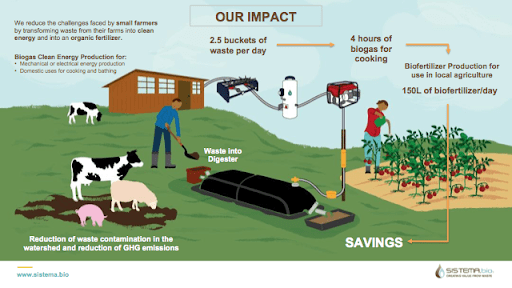

Such issues weighed heavily on TaroWorks client Sistema.bio – which manufactures, installs and maintains biodigesters that generate biogas for clean cooking and fertilizer for smallholder farmers. As it expanded operations from Latin America to South Asia and the African continent, it experienced significant growth in biodigester installations (from 1,000 units in 2015 to more than 17,000 units by 2020). That growth led to increased product shipments from Sistema.bio’s manufacturing plant in Mexico to expanding markets in India and Kenya.

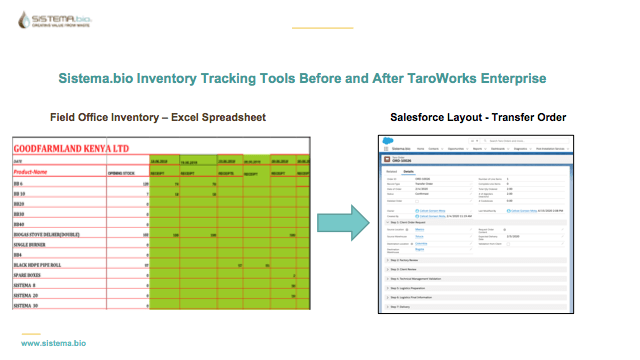

The number of warehouses ballooned from six to 15 to cover increased product sales and an expanding product line. Sistema.bio knew that spreadsheets and decentralized communication channels wouldn’t scale as a last mile inventory management system since this approach offered no real-time glimpse of product availability. That was a weakness, which could impact biodigester sales and subsequent field support for installation and maintenance.

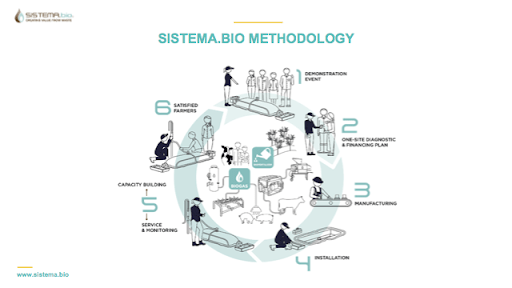

For a farmer to use Sistema.bio’s biodigester successfully involves many processes and requires coordination between different team member roles. It all starts with educating potential customers on the product’s benefits and getting sales leads from demonstration events. Then, on-site diagnostics are done to determine which biodigester size will add the most value to each particular farm.

Such diagnostics involve factors such as type of livestock, number of animals, fertilizing needs and energy demand. Sistema.bio manufactures their own biodigesters, which are installed by their technicians, and farmers are trained to use each system.

Because its operations happen in remote areas, Sistema.bio started using Salesforce’s cloud-based CRM in 2015 and TaroWorks’ offline mobile field service app in 2016 to support biodigester sales, installation and servicing operations in rural and offline areas. They even digitized an asset-based financing program designed to attract new customers.

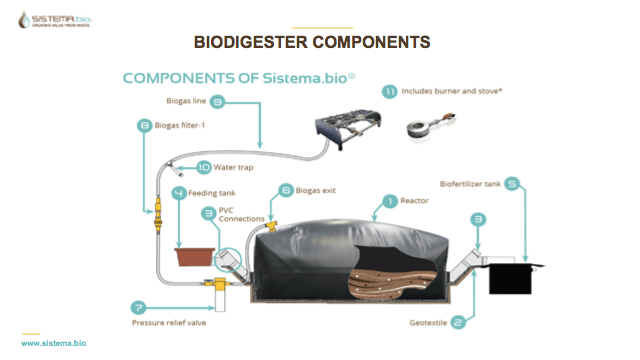

After they enhanced management of these core field operations with TaroWorks and Salesforce, Sistema.bio hoped to also use the technology to monitor product levels in warehouses using an inventory system as part of their manufacturing stage (each biodigester system has at least 11 component parts).

There was also a need to better handle product procurement from suppliers and to direct distribution to each customer in the last mile. In other words – Sistema.bio wanted to implement a full last mile inventory management system across their entire supply chain, to complement their basic service delivery and accommodate their growing logistics network.

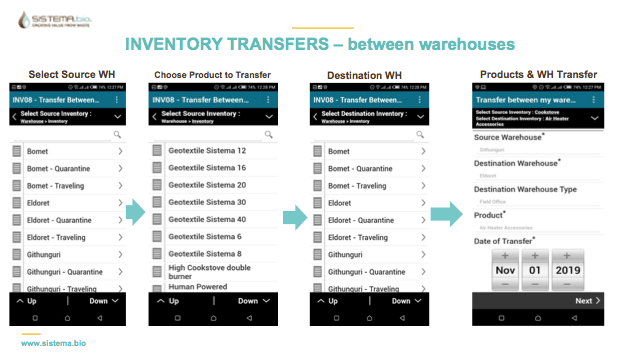

Sistema.bio achieved those goals using TaroWorks Enterprise, a mobile inventory management platform that helps track stock levels and product movements between suppliers, warehouses and last mile distribution agents – even from offline smartphones or tablets. During a recent webinar, Sistema.bio shared how it’s using TaroWorks Enterprise and Salesforce to digitize its last mile inventory management system to better track incoming and outgoing stock of biodigester components at warehouses around the world and to provide reliable delivery to its farmer clients.

Maxence Affre, Sistema.bio’s Global Technical Director and Himanshu Mishra, a Sistema.bio Technical Director based in India, gave an overview of how TaroWorks started by helping manage service delivery and is now used to guide the organization’s supply chain.

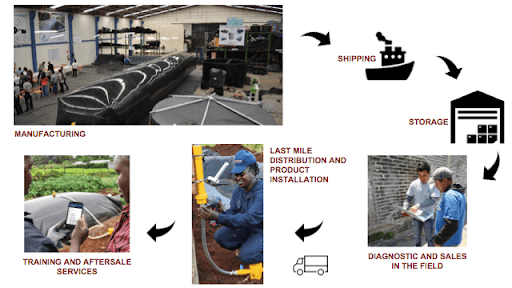

To build an inventory management system for Sistema.bio, we first had to understand the path its products took from manufacturing plant to last mile customer. For example, Maxence explained that once a newly manufactured biodigester leaves the factory in Mexico, it is shipped by boat to Kenya (through the Carribean Sea, across the Atlantic Ocean, around the tip of South Africa and on to the Kenyan coastal port of Mombasa on the Indian Ocean).

The biodigester container is then transported by train to Sistema.bio’s national warehouse in Nairobi, the distribution center, and is eventually driven to one of Sistema.bio’s rural field offices in Kenya. Then the last mile delivery happens. From the field office, the biodigesters are driven to the farms to be installed. Finally, clients are trained in their use.

The biodigester is stored in a local warehouse while company sales and technical teams qualify potential customers and close purchases with smallholder farmers. The product’s final trip is from the local warehouse to the customer’s farm where it is installed, the client is trained in its use and it is maintained by the Sistema.bio field team.

The goals and objectives of any Sistema.bio last mile inventory management system we developed were to:

The new inventory system would also have to perform a number of tasks including:

According to Maxence, implementing TaroWorks Enterprise resulted in a number of benefits:

“…the main benefits of TaroWorks Enterprise is to confirm whether or not we have enough product in store to be able to plan product movements,” Maxence said during the webinar. “Different field offices can request transfer from (one) warehouse to another warehouse and we can track those movements. We can also keep track of the return products in case we have a product that goes back from a client to our field office and we can keep track of the products we are purchasing locally.”

Another advantage of using mobile and cloud technology to centralize Sistema.bio’s last mile inventory management system is that each person in the process, who has a different role to play, can now have access only to the part of the process they need to control, said Maxence.

Other pluses of an inventory management tool built on TaroWorks and Salesforce include providing real-time data to the field about where along the supply chain the product is at any given time. This increased transparency improved the reliability of biodigester delivery to the smallholder farmers who purchased the product.

Finally, there’s the ability to collect data in the field while using the TaroWorks mobile field service app offline. Then, a two-way flow of information is created between a warehouse and headquarters as data is synced from the mobile device to the cloud database when in range of wifi or mobile phone service. This functionality brings logistics management capabilities to areas where there is little to no connectivity.

With “the inventory visualization we have in Salesforce … we are able to track every single product and any single new product we are producing today and we are able to see the quantity that is available – that is physically available – the quantity that is committed to a client and the quantity that is available to be sold,” said Maxence. “So that’s really easy to have a good overview of the quantities in every single warehouse we have all over the world.”

POST TOPICS

Sign up to receive emails with TaroWorks news, industry trends and best practices.

TaroWorks, a Grameen Foundation company.

Site by V+V