Search

With the rise of new natural disasters, wars, and the need for vaccines and medication, we are reminded of the extreme challenges faced by last mile distribution – including getting essential products to people and communities, quickly.

TaroWorks has worked with over 140 nonprofits and social enterprises to deliver impact in hard-to-reach areas all over the world. Many of these organizations have inventory components to their mission, like distributing water filters or critical medications, and have important needs to track inventory levels – especially as they scale to new geographies, or provide more items. To support these needs, we have developed TaroWorks Enterprise – a mobile offline inventory management system that helps track stock levels and product movements between suppliers, warehouses, and last mile distribution agents, all while offline from a smartphone or tablet.

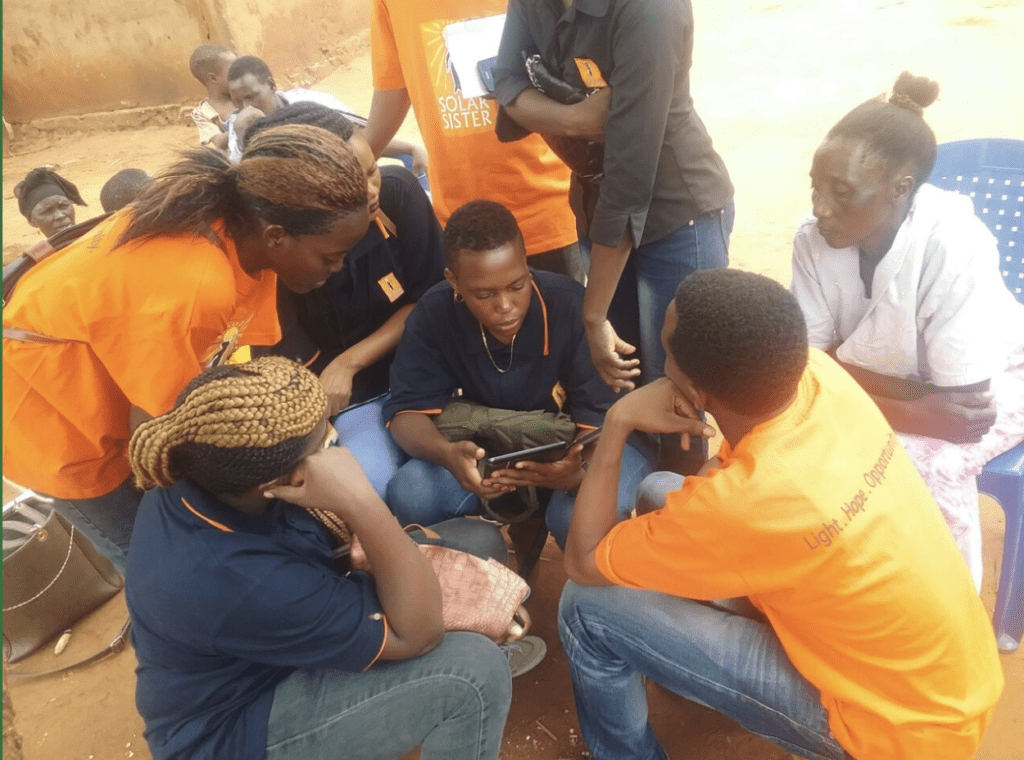

On June 22, 2022, we joined Natasha Wheatley, Data and Systems Manager of Solar Sister for a webinar to discuss how Solar Sister is using TaroWorks Enterprise to transform their offline inventory management system to better track their assets.

Solar Sister recruits, trains, and supports women from energy-poor areas who are interested in entrepreneurship and passionate about bringing light and clean energy to their communities. They have reached over 3.4 million people with clean energy and recruited over 7,400 entrepreneurs, 87% of whom are women.

Solar Sister has a global team that includes a small staff in the United States, and sizable in-country staff members in each of their working countries. In the United States, they have hands-on administration staff who have deep knowledge of their inventory system to make critical decisions around what products they need to bring into their inventories. On the ground, Solar Sister employs country directors to understand what is happening across their network and ensure that the full potential of all entrepreneurs is being realized. Finally, Solar Sister relies heavily on their Business Development Associates (BDA’s), as they maintain the inventory warehouses. These team members are the primary vehicle for logging inventory movements and understanding what products the entrepreneurs need.

Since 2012, Solar Sister has been using Salesforce to track its success and build entrepreneurship. They soon started using TaroWorks to reduce human errors and speed up the process in which their BDAs could forward the information they gathered in the field from the entrepreneurs to the country HQ offices. Before TaroWorks, they were relying on different communications, including phone calls, emails, and SMS texts which had to then be entered into Salesforce by HQ staff. Using multiple communications tools caused delays and missing information. To speed up the process, Solar Sister introduced TaroWorks for data collection.

In 2020, Solar Sister looked to revamp its system to keep up with their evolving business practices. To do so, they looked to TaroWorks Enterprise to focus on their offline inventory management and manage their payments and account balances. At this time, they faced these specific inventory challenges:

To revamp their system, Solar Sister worked with Mogli on an 18-month intensive process, from initial conversations to a finalized operating system with trained individuals.

Since the success of the TaroWorks Enterprise implementation, Solar System has leveraged key elements of its offline inventory management system including the introduction of ‘products,’’ inventory movements and inventory audits, the concept of a ‘price book, and a system for returns and replacements.

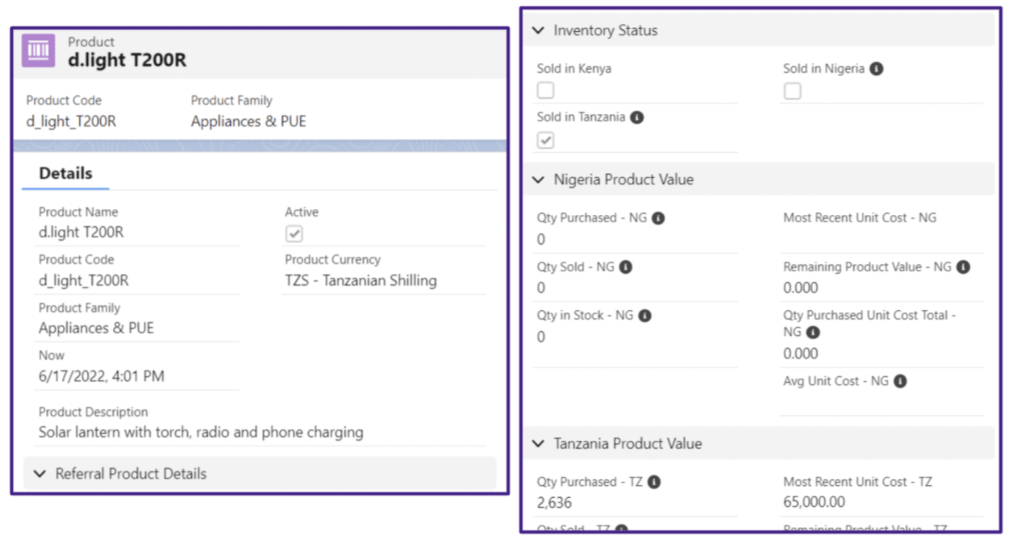

Solar Sister created a standard product name for each item they keep in their inventory. Previously, the products had different information depending on their location. Now the product information is standardized regardless of where the product lives. This resulted in the simplicity of the movement of products between warehouses.

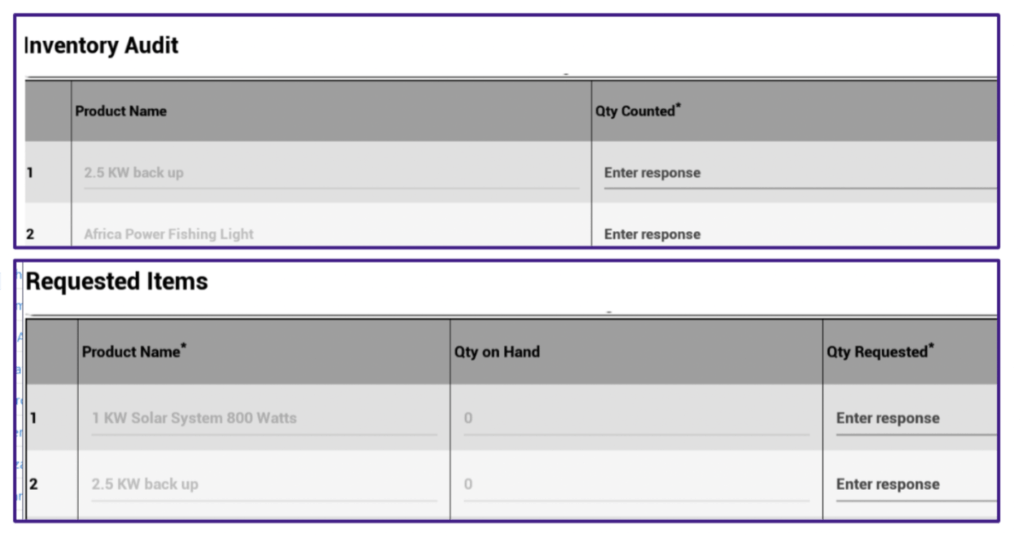

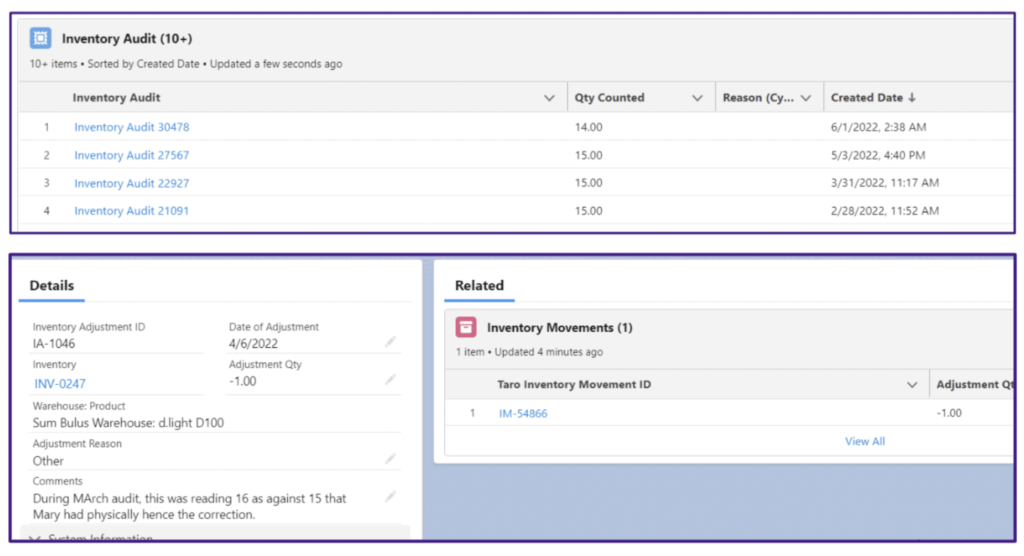

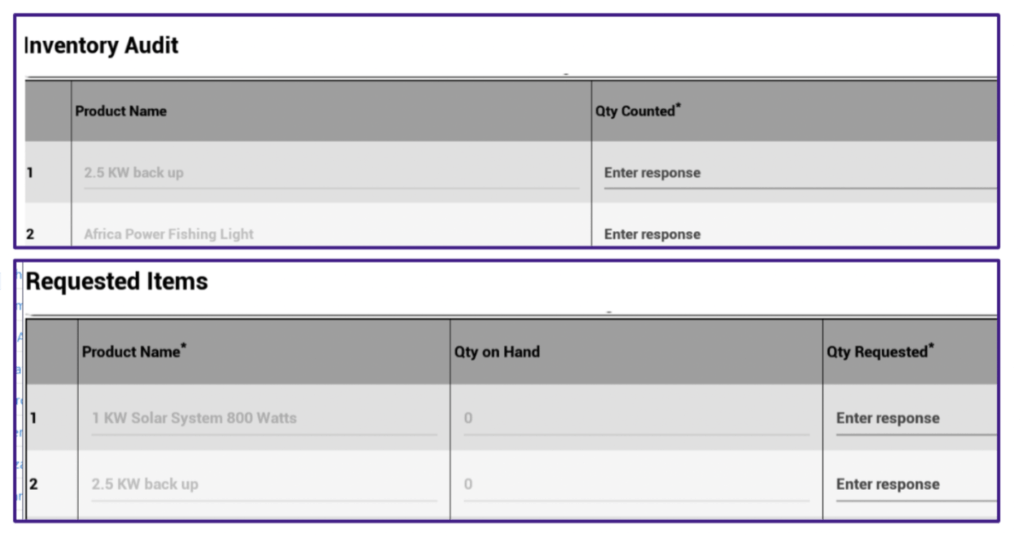

Previously, it was difficult to determine where products in warehouses came from or where they went. With TaroWorks Enterprise, records are created each time new products are purchased, sold, or moved. The field staff submits monthly audits for their warehouses with documentation. Now, administrators can update Solar Sister’s inventory levels, based on their audit submissions. Errors or discrepancies in counts can be troubleshot and almost immediately resolved.

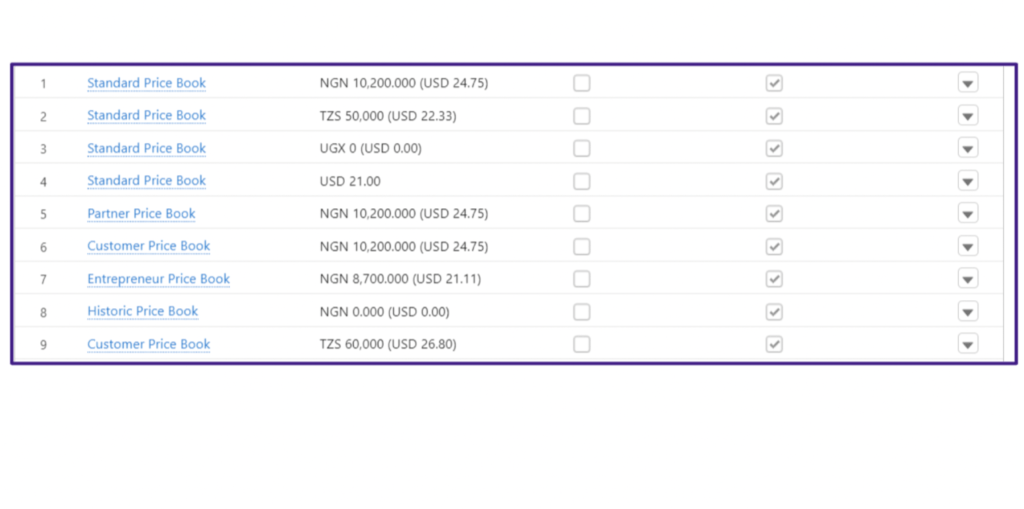

Before the use of TaroWorks Enterprise, a price change would change all the historical sale records for a warehouse. Now, the prices are updated for a product only for new sales and users can select from different pricing options. They can also zero out a price for a single transaction when appropriate. This system results in accurate historical revenue numbers and allows for administrators to reconcile accounts receivable at any point.

Solar Sister created a system allowing for returns and replacements. Previously, there was no zero pricing, meaning that replacements were essentially tracked offline and then manually adjusted in the database. Now, BDAs can easily replace faulty products while accepting a return as a dedicated job that automatically makes inventory adjustments. Products being written off or sent back to suppliers have their own “warehouse” to manage levels and costs. This results in better knowledge of what they have spent replacing products and what to expect from the supplier.

For Solar Sister, switching to TaroWorks Enterprise was a successful, but long process. They did a lot of work to critically think about how everything would fit.

“Now we have more accurate sales numbers, accurate inventory records and purchasing is so much more efficient” – Natasha Wheatley.

Natasha stated that through the process, Solar Sister learned two valuable lessons:

“It is important to be intentional about thinking about what your staff actually needs to see, and what is useful for their jobs”.

POST TOPICS

Sign up to receive emails with TaroWorks news, industry trends and best practices.

TaroWorks, a Grameen Foundation company.

Site by V+V